typical fireplace spark arrestor cad 3d drawings

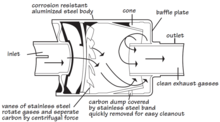

Centrifugal blazon spark arrester

A spark arrester (sometimes spark arrestor) is whatever device which prevents the emission of flammable droppings from combustion sources, such equally internal combustion engines, fireplaces, and wood burning stoves.

Spark arresters play a critical part in the prevention of wildland burn and ignition of explosive atmospheres. Consequently, their use is required by law in many jurisdictions worldwide.

Applications [edit]

Engines [edit]

Steam [edit]

Internal spark arrester mesh on a model steam locomotive

Large spark-absorbing chimney on an American locomotive

Spark arresters for steam locomotives may exist internal (in the form of wire mesh within the smokebox) or external. The earliest platforms for spark arresters in the United States were steam locomotives. Wood- and coal-burning locomotives produce embers which are readily transported by the wind. One popular design was the Radley-Hunter spark arrester, which used a spiral-shaped cone to divide embers from the exhaust flow past centrifugal force.[1]

The problem of equipment-started fires continued into the 20th century. Academy of California, Berkeley researchers J.P. Fairbank and Roy Bainer provided the start known academic inquiry on the subject.[two] Their experiments demonstrated that hot particulate matter larger than 0.023 inches (0.584 mm) in bore was capable of igniting wildland fuels.

Internal combustion [edit]

In the 1950s, the U.s. Forest Service became interested in reducing the number of fires started by logging equipment in the National Forest System.[iii] This interest led to a partnership with the Society of Automotive Engineers and the development of the following examination standards for spark arresters:

- SAE J335 – Multiposition Small Engine Frazzle Organisation Burn down Ignition Suppression

- SAE J342 – Spark Arrester Test Procedure for Large Size Engines

- SAE J350 – Spark Arrester Test Procedure for Medium Size Engines

Modern technologies take largely eliminated the product of large particulate affair from internal combustion engines. Withal, as engines wear, carbon deposits can build upwardly on the internal walls of the engine. When these deposits break costless, they go out through the exhaust system and present a potential fire hazard. Vehicles without properly performance spark arresters have been suspected of starting numerous wildfires, including the devastating track fire near Raton, New Mexico in June 2011.[4]

Today, spark arresters can be establish as OEM or aftermarket components on many types of equipment, such as large agricultural machines, off highway vehicles (OHVs), and small engines (chainsaws, string trimmers, leaf blowers, etc.).

Buildings [edit]

Spark arresters are likewise fitted to the peak of a flue (or a chimney pot) to prevent floating embers from a fire (specially one burning forest) setting light to a flammable roofing surface (shingle, thatch, or bitumen-felt) or falling onto combustible material on the basis. Such a spark arrester typically consists of a double layer of metallic mesh, which catches the ember and allows the flue gas to escape.

Big power station boilers are commonly fitted with electrostatic precipitators.

Electric equipment [edit]

Types [edit]

Centrifugal [edit]

Centrifugal type spark arresters utilize stationary vanes, baffles, or other devices to trap large particles past centrifugal force. These spark arresters are typically found on heavy agronomical and construction equipment (tractors, combines, bulldozers, etc.), but some accept been developed for motorcycles and other all-terrain vehicles.

Screen type spark arrester

Screen [edit]

Screen type spark arresters apply a physical mesh to foreclose big particles from leaving the exhaust system. This is the simplest and almost common type of spark arrester. Screen type devices are used on most motorcycles, ATVs, and pocket-size engines.

Electrostatic precipitator [edit]

Regulatory requirements [edit]

United states of america [edit]

A U.s.a. Forest Service "Spark Arrester Required" sign posted in a woodcutting area

Laws governing spark arrester use in the The states depend on the jurisdiction. Internal combustion engines operating on USDA Woods Service and almost other federally managed lands must encounter the requirements of the Code of Federal Regulations 36 CFR 261.52.[5] This mandate requires the operator to have a certified and properly maintained spark arrester installed at all times. Many state and local state management agencies defer to the federal requirement.

An unapproved spark arrester installed on a motorbike

Exemptions exist for automobiles legally registered with their state's section of motor vehicles. During periods of extreme fire danger, land managers may prevent the use of all motorized equipment, fifty-fifty if a properly performance spark arrester is installed. Spark arrester inspections are performed by trained agency police force enforcement or burn prevention personnel. They may occur on an individual basis, or as part of an inspection checkpoint during decorated recreation weekends. Operators caught using unqualified or modified devices could be cited. Penalties for violating spark arrester laws depend on the issuing agency. If it is determined a noncompliant vehicle was responsible for starting a fire, the operator could be held liable in civil or even criminal court.

Certification testing of spark arresters is performed by the USDA Forest Service Engineering science and Development Center in San Dimas, CA. The technical requirements are outlined in Forest Service Specification FS5100-i. All spark arresters meeting the requirements of 36 CFR 261.52 must be certified and listed in the USDA Forest Service Spark Arrester Guide. This guide is a comprehensive directory of all qualified products available in the Usa, and is published biannually. The Spark Arrester Guide is used by field inspectors and consumers to verify product certification status. Manufacturers pursuing spark arrester qualification in the United States should consult the USDA Forest Service'due south "Manufacturer'south Submission Procedure" for both general purpose[6] and pocket-size engine[7] spark arresters.

Run across also [edit]

- Flame arrester

Notes [edit]

- ^ United states patent 7040, James Radley and John W. Hunter, "Spark Arrester", issued 1850-01-22

- ^ Fairbank, J.P. and Bainer, R. Spark Arresters for Motorized Equipment. Bulletin 577, University of California Agricultural Experiment Station (1934)

- ^ USDA Woods Service Technology & Evolution Program An Introduction to Spark Arresters - Spark Arresters and the Prevention of Wildland Burn (2003) [1]

- ^ Mestas, Anthony (19 June 2011). "ATV ignited Track Fire". The Pueblo Chieftain. Pueblo, CO.

- ^ United States Code of Federal Regulations 36 CFR 261.52

- ^ USDA Forest Service Engineering & Development Programme Manufacturer Submission Procedure for the Qualification Testing of General-purpose, Screen, and Locomotive Spark Arrester Exhaust Systems (2005)[2]

- ^ USDA Wood Service Technology & Development Program Manufacturer Submission Procedure for the Qualification of Multiposition Modest Engine Spark Arrester Exhaust Systems (2001)[3]

External links [edit]

- Off-Highway Vehicle Spark Arresters Tech Tip (USDA Forest Service)

- General Purpose Spark Arresters Tech Tip (USDA Forest Service)

- Spark Arrester Constabulary - Land of California

drummondounts2000.blogspot.com

Source: https://en.wikipedia.org/wiki/Spark_arrestor

0 Response to "typical fireplace spark arrestor cad 3d drawings"

Post a Comment